The advanced Industrial engineering learning factory is a cooperation of the Fraunhofer Institute for Manufacturing Engineering and Automation IPA with the Institute of Industrial Manufacturing and Factory IFF of the University of Stuttgart.

With this professional training for industrial engineering, work planning and production optimization you:

- strengthen your responsiveness to market changes and recognize the relationship to the tasks of production optimization

- learn methods for identifying weaknesses in the factory and for value stream-oriented production planning

- apply the learned methods independently in practice-oriented scenarios

(Introduction of new products and technologies, product mix shift, etc.) - get to know the potential of digital tools for planning support

- put the planning results, which have been worked out in the team, into the learning environment and experience the planning success in the ongoing production

- benefit from experienced speakers from the Fraunhofer Institute for Production Engineering and Automation IPA, the Institute of Industrial Manufacturing and Management (IFF) and the German MTM Association e.V.

The Training Center has a homepage of its own in German.

Contact:

Dipl.-Ing. Erwin Groß

Manager Learning Factory aIE

Phone: +49 711 970-1054

Mobile: +49 162 2684346

E-Mail

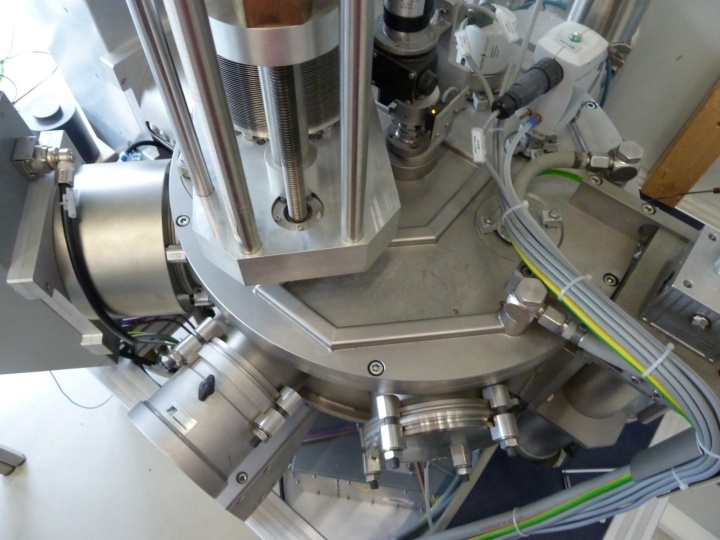

In the production process of the learning factory, we use an ARBURG

ALLROUNDER 220S to make our injection moldings ourselves.

On the injection molding machine inserts are made in different colors for our aluminum cups.

This enables us to create different versions of our desk set and to map further customer requirements in the training scenario.

Contact:

Dipl.-Ing. Erwin Groß

Manager Learning Factory aIE

Phone: +49 711 970-1054

Mobile: +49 162 2684346

E-Mail

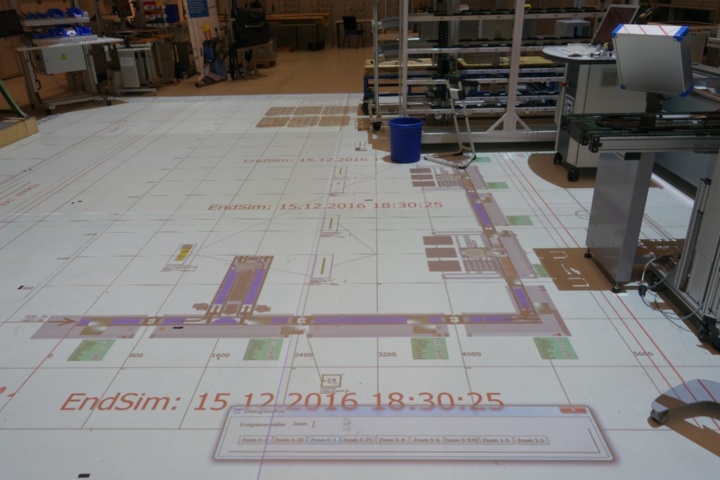

The IFF has developed a continuous factory coordinate system for transformable production systems and has implemented it in the learning factoryfor advanced industrial engineering. The factory coordinate system enables the real-time, scaling-independent combination of the digital image of the factory (digital shadow) and real production. For this purpose, various detection systems installed in the hall are grouped into an order system according to the necessary accuracy class and the acquired data, based on their resolution, time-related in a uniform coordinate system. Through the resulting digital shadow of the complete production, the system complexity can be reduced task-specifically. Necessary decisions can be supported by real-time central or decentralized simulations with real-time data so that system changes - due to new restrictions - can be achieved faster and more economically. By reflecting the digital shadow back into real production via the installed projectors, deviations in real time can be made visible, problems can be remedied and downtimes can be reduced before they occur. This is intended to strengthen and secure the competitiveness of networked production facilities.

Contact:

Dipl.-Ing. Thilo Schlegel

Phone.: +49 711 685-61892 | +49 711 970-1058

Mobil: +49 159 058 776 08

Fax: +49 711 685-51892

- Application Center Industrie 4.0 at the Fraunhofer IPA

Complete informationen about the Application Center Industrie 4.0 you can find here.

Hall Manager