Coating systems have become economically the most important and flexible surface technology.

The process chain coating technology is at the forefront of the development of new coatings and paint raw materials, the application of paint and the development, modeling and simulation of production-oriented coating processes and systems and their implementation. Process and damage analysis can be carried out quickly and professionally, using constantly updated quality and testing methods using state-of-the-art facilities.

The process chain coating technology is at the forefront of the development of new coatings and paint raw materials, the application of paint and the development, modeling and simulation of production-oriented coating processes and systems and their implementation. Process and damage analysis can be carried out quickly and professionally, using constantly updated quality and testing methods using state-of-the-art facilities.

Pigments and Coatings

- Development of structure-property relationships for paints, paint raw materials and pretreated surfaces

- Development of suitable testing techniques for paints and coatings

- Testing and simulation of long-term behavior of coatings

- Conception of novel particulate materials and binders

- Surface design and engineering of micro- and nanoscale fillers and pigments

- Coatings with high weather and chemical resistance

- Rapid tests for the evaluation of nanoparticles and binders

- New coating systems for special functions

- Optimization of development cycles and quality control

- Benchmark investigations in the process chain coating technology

Optimization of Surface Engineering Processes and Systems

- develop and optimize innovative, economical surface pre-treatment and painting processes and systems

- analyze weaknesses and savings potential as well as select and develop improved technologies

- design and validate low-loss spray painting technologies for various substrates

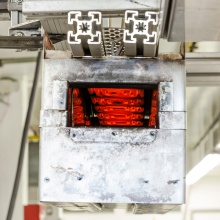

- optimize radiation hardness of paint coatings

- modeling and simulating pretreatment and painting processes, air flows in cabins and dryers, separation processes during spraying, electrocoating and powder coating as well as air circulation and radiation curing

- recycle paints and minimize energy consumption

- staff training

Quality and Testing Technology

- systematic investigation of the physical mechanisms for the function and stress of coatings

- error diagnostics, clarifying failure mechanisms

- adapt, develop and provide standardized measuring and testing technology

- test varnishes, coatings and components

- automated control of painting processes and process baths

- record painting plant operation by measurement

Dr. rer. nat. Michael Hilt

Department Manager

Phonel: +49 711 970-3820

E-Mail

The application of electrochemical (galvanic) processes not only requires increasingly precise material and geometrical properties, but also process-safe and reproducible application technologies. This is reflected in the fact that we pursue the entire R & D chain from process development to industrial plant technology. This width and - within surface technology - the focus on the electroplating technology is our extraordinary strength.

Dr.-Ing. Martin Metzner

Department Manager

Phone +49 711 970-1041

E-Mail

Department Manager

Michael Hilt MBA

Dr. rer. nat.Head of Department Surface Technology