Ongoing Research Projects

In the Cognitive Production Systems department, we focus on developing and applying advanced control and prediction algorithms to address issues related to robustness and reliability in production systems. At the same time, we ensure that the entire system remains flexible and can adapt to process changes. To improve robustness, reliability, and flexibility simultaneously, we use machine learning and artificial intelligence methods, including reinforcement learning, multi-layer perceptrons, and others.

Research Topics

The research topics of the department are as follows:

- Development and application of machine learning methods in an industrial environment

- Architectures and algorithms for cognitive robotics and automation technology

- Integration of cyber-physical and cognitive means of production in networked value creation systems

- Safe, reliable, and traceable use of artificial intelligence in production

- Theory-guided data science for forecasting and health management

- Physics-informed machine learning and data-efficient artificial intelligence in production

Vision:

The DigiAutoFab project aims to fully digitalize the entire process chain for additively manufactured plastic components using the laser powder bed fusion process (PBF-LB/P), from design through manufacturing preparation, production, and downstream processes.

Objective:

The goal of digitalization is to achieve continuous traceability of components and the targeted development of process knowledge. This will enable rapid optimization of processing parameters using machine learning approaches and improve reproducibility and transferability between systems. In this way, the use of additive manufacturing processes in the automotive industry for the production of pre-series and spare parts can be made possible.

By building a digital twin, efficient design and layout workflows can be developed, and machine learning methods can be utilized to enable the additive manufacturing of functional components in application scenarios with a robust and efficient overall process. These new capabilities then allow the use of currently difficult-to-process but economically more attractive materials and the processing of recycled materials, thus contributing to cost reduction and sustainability of additive manufacturing.

The individual components, methods, interfaces, and algorithms are developed along two use cases, which will also be used in a technology demonstration at the end of the project and serve as a basis for deriving business models that can address the described application scenarios. The use cases are as follows:

- Injection molding-equivalent pre-series parts

- Injection molding-equivalent spare parts

The final exploitation strategy of DigiAutoFab relies on four interconnected activities:

- Development of the key exploitable results (KER)

- Elaboration and refinement of exploitation paths, including the development of strategies for protecting intellectual property and knowledge rights, as well as ongoing market landscape analysis

- Bridging the project end results with potential commercial applications and roadmapping for long-term impacts post-project completion

- Simultaneously exploring cooperative business models: continuously assessing whether the digitalization solutions developed in the project can enable business models across company boundaries

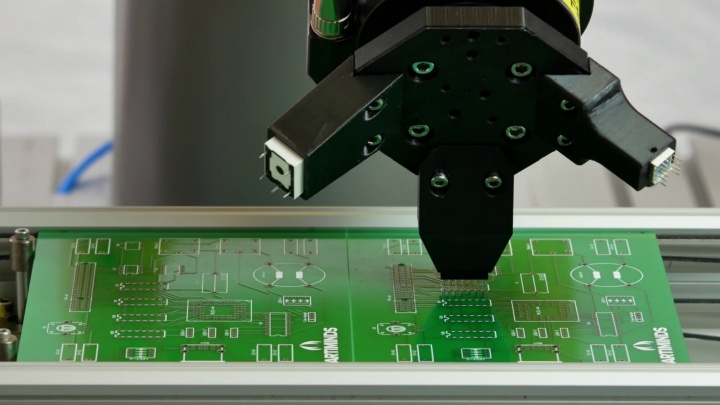

AIQualify: Framework for the qualification of AI systems in industrial quality inspection

The manufacturing industry and its customers are increasingly emphasizing high-quality standards. Instead of manual quality inspections, which can be inefficient and error-prone, some industries increasingly rely on automated inspections, e.g., machine learning (ML) methods. However, there is still a lack of suitable standards and development methods to prove the suitability and qualification of an ML-based AI system. Concerns regarding the reliability or accuracy of ML-based AI systems have so far prevented their widespread industrial use.

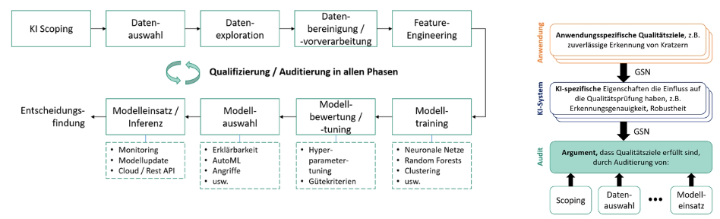

The project aims to develop a software framework for the qualification and auditing ML-based AI systems in industrial quality inspection. The framework consists of a process model including software-supported methods and tools that make it possible (a) to determine and formulate test and evaluation criteria and (b) to accept the AI system according to these criteria. The framework should be modular to integrate and expand testing and auditing modules easily. The framework should enable small and medium-sized enterprises (SMEs), in particular, to qualify third-party AI systems to assess their performance even without their own AI specialists. The framework should also be usable for AI service providers for self-assessment or independent certification testing bodies.

This project proposes a systematic determination and formulation of application- and AI-specific test and evaluation criteria for the various development phases of an AI system based on so-called argumentation structures. The core element of the argumentation structure is the main goal to be achieved by the AI system, for example, that a specific pseudo-error rate is not undercut. This main objective can be broken down into sub-objectives or criteria to be fulfilled for further structuring. In addition, all assumptions made and contextual information must be integrated into the argumentation structure. In order to be able to provide a structured argument for the fulfillment of the main objective, the argumentation structure also includes the system or process-related evidence required and to be provided. The argumentation structure is to be used when auditing the AI system along the various development phases. Therefore, this project aims to develop a computer-aided assistance system as part of the software framework to support the creation of argumentation structures based on ready-made templates corresponding to the application context of the quality checks and centrally manage the created argumentation structure. A computer-aided auditing platform is to be developed for this purpose.

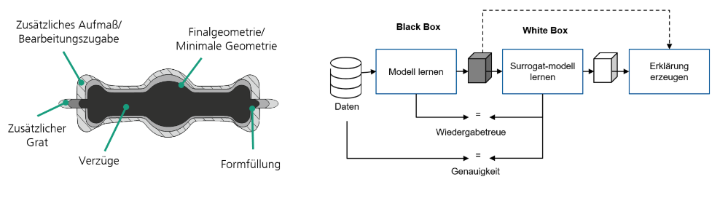

SPP 2422: Transparent, AI-supported process modeling in drop forging

Hot forging processes are subject to many variables and boundary conditions. The forging process is sensitive to interacting process fluctuations or unstable process control. Fluctuations in the insertion temperatures or the application of the lubricant, in particular, lead to underfilling, and the component is assessed as a reject. Mass additions ensure a more stable process in die forging. This results in burrs, which later have to be removed with much energy and require additional material. Stabilizing the process by forming burrs, therefore, has a negative effect on material and energy requirements. Many geometries are also susceptible to distortions that require further reworking outside the permissible tolerance. Fluctuations in the process parameters and unknown interactions influence the quality of the parts.

The research project aims to improve quality characteristics in the drop forging process by better understanding the interactions. Data-based models, in combination with global explainability methods, will help to identify previously unknown correlations and process fluctuations. In this way, approaches can be developed that allow process stabilization even with lower safety factors such as burrs or oversizes through an adapted active surface design. To achieve this, domain knowledge is first collected and condensed, and component quality data and process data are automatically generated to create reference data sets. This data is used to develop a machine learning method that can make predictions about quality characteristics based on process data. Finally, a white box model is developed to identify process variables influencing component quality. In the future, this will be used to optimize the die surface design for the present process and achieve transferability to other drop forging processes.

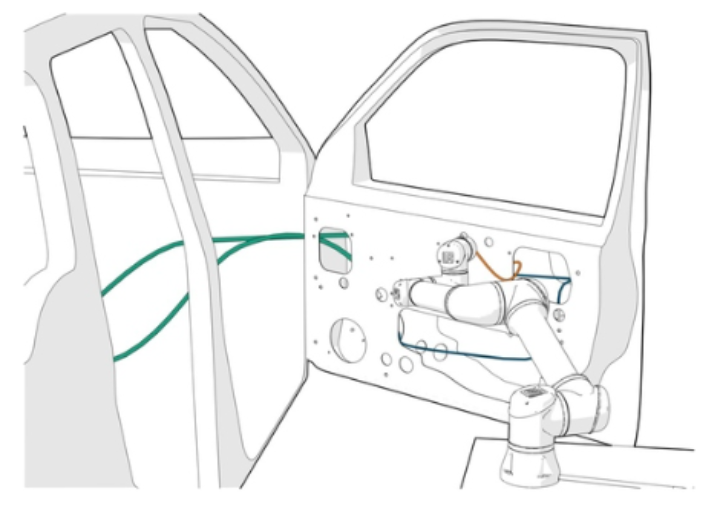

RoboCable: Robot-assisted manipulation of flexible components with high variance and process uncertainty in the production of electric vehicles

Flexible components such as cables and cable harnesses play a key role in the production of electric vehicles. However, they cannot be handled automatically due to a lack of robust processes. The "RoboCable" project researches new AI methods for robot-assisted handling and manipulation of flexible components.

The project is looking at a combination of the following technologies

- Position estimation of filigree flexible components using optical sensors

- Model-based matching of sensor data and digital component model

- Skill-based robot programming for the implementation of complex and force-controlled movements

- AI-based selection and parameterization of suitable robot skills

- Reinforcement learning for robot control

- Use of a physics simulation environment as a digital twin of production

This combination enables the robot to learn new assembly tasks virtually in the simulation environment to account for the high variances of bendable components and inherent process uncertainties. Ongoing tasks can be carried out in parallel without interruption. In the spirit of VISION ZERO, programming, downtimes, start-up times, and defects are minimized.

The project was launched on January 1, 2023, as part of the Innovation Campus Mobility of the Future ICM.

University of Stuttgart: Institute for Control Engineering of Machine Tools and Manufacturing Units (Prof. Verl) https://www.isw.uni-stuttgart.de/

KIT Karlsruhe: Institut of Industrial Information Technology (Prof. Heizmann) https://www.iiit.kit.edu/index.php

Fraunhofer IPA Stuttgart: Department of Robot and Assistive Systems (Dr. Kraus) https://www.ipa.fraunhofer.de/de/Kompetenzen/roboter--und-assistenzsysteme.html

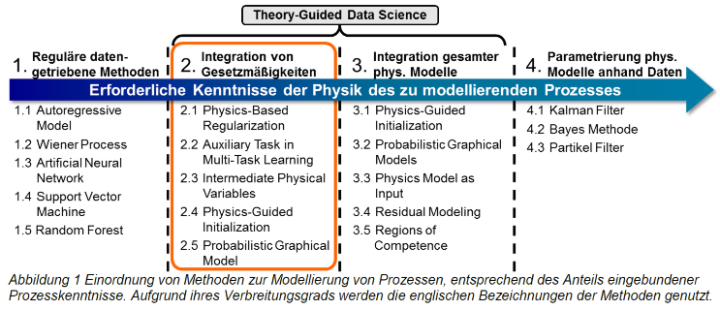

TGDS: Theory-guided data science for cross-application optimization of data-driven diagnostic and prognostic methods in prognostics and health management

The field of Prognostics and Health Management (PHM) deals with diagnosing the current state of degradation of technical systems and predicting the further development of this state. The aim is to provide information that can be used in health management for planning and coordinating maintenance processes or system adjustments. In the literature, methods for condition diagnosis and prognosis are usually divided into physical model-based, data-driven, and hybrid methods. The latter serve to compensate for the inadequacies of purely data-driven methods by incorporating knowledge about the system under consideration, which is, however, considered insufficient for holistic modeling of the system. This is because basic knowledge about the system and the laws of its degradation process is usually available. This branch of research is called Theory-Guided Data Science (TGDS) and aims to reduce the deficits of data-driven methods.

The research project aims to integrate cross-application laws and boundary conditions in PHM into data-driven methods for condition diagnosis and prognosis. One example is that the technical system under consideration cannot self-heal. This predominantly occurring property means that the degradation state of the system must be monotonically increasing. The integration of such prior knowledge should enable an improvement of the extrapolation in areas with little or no training data, as well as compliance with the laws of the system to be modeled. The approaches to be pursued are Physics-Based Regularization, Auxiliary Task in Multi-Task Learning, Intermediate Physical Variables and Physics-Guided Initialization (see Figure 1). While theoretical preliminary work already exists, the research project will develop dedicated solutions for the field of PHM, which will have a correspondingly broad impact due to the central focus on taking into account the cross-application characteristics of the regularities.

Completed Projects

The AI online course from the AKIPro project imparts application-oriented knowledge about AI in industrial production and helps to put this technology into practice. It was handed over to the AI campus and is now available on their learning platform. The plan is to integrate the service into IFF courses and formats at the Black Forest Campus. What is special: The AI course is open not only to students and experts, but to anyone interested

The sustainable remanufacturing/refabrication of appliance components requires much manual work. While new production benefits from a high degree of standardization of the components in each production step, the wear and tear of each component has a very different effect on the shape or surface properties during remanufacturing. This makes automation much more difficult and makes new production - although significantly less sustainable - more economical. At the same time, there is the challenge of an increasing shortage of skilled workers, which is why there is a great need for automation solutions in remanufacturing.

This project uses artificial intelligence (AI) to reconcile sustainability and cost-effectiveness. AI allows automated individual adaptation of the processing of a workpiece. This makes automation applicable and remanufacturing competitive in the free market compared to new production. The AI-based machining system combines sensors for object measurement and visual inspection with executing robots and suitable machining tools and an intuitive interaction system for humans. Task planning and force-controlled processing by the robot use state-of-the-art machine learning methods.

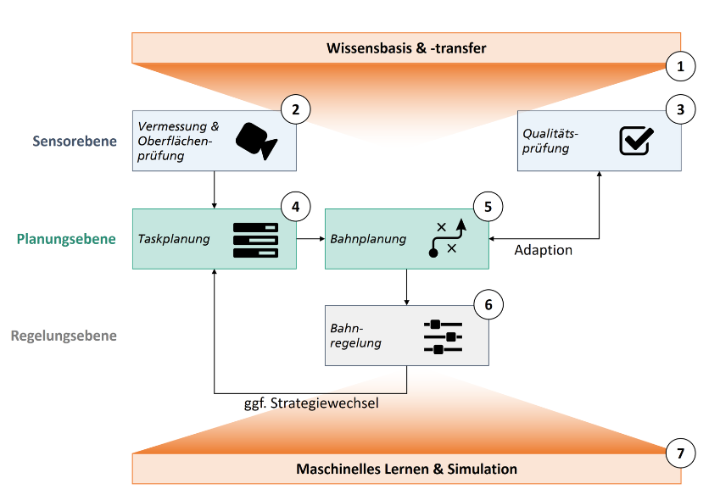

With the current state of the art, very frequent manual and therefore expensive adaptation of robot programs is necessary, so operation cannot be economically designed. Robots should now be able to program and set themselves up independently for the processing task. Specifically, the processing system consists of various interacting modules (see illustration). Domain and expert knowledge can be stored via a knowledge base in the form of an ontology and in a task library and incorporated into the robot controller (1). Sensors measure the workpiece to be processed. Deviations from the standard state of the workpiece can be determined based on the measured values (2). During the machining process, the sensors continuously measure and evaluate the workpiece condition and the machining quality (3). Task planning defines the robot's abstract machining activities and target movements (4). The path planning generates a robot path from the selected tasks, which must be traveled for processing (5). Path control (6) aims to quickly adjust the force and position paths specified by the path planning in order to achieve the desired processing result. The processing of the sensor data and the various planning and control methods use ML methods in combination with knowledge-based approaches (7). A simulation is used for automated robot programming, allowing the robot to plan the activities required for a machining task optimally.

An adaptive, digital overall system for the automated reprocessing of different device components is the aim of the project.

FutureWorkLab is ann Innovation laboratory for labour, humans and technology in Stuttgart. The departmentAbteilung Cognitive Production is engaged in FutureWorkLab II .

Flexible robot programming for assembly tasks is still complex. The aim of the “Rob-aKademI” research project is to improve this. The technologies used, especially machine learning, are intended to make programming easier and more autonomous.

The partners in the “Rob-aKademI” research project, including the Institute for Industrial Manufacturing and Management IFF at the University of Stuttgart and the Fraunhofer IPA, are developing technologies intended to simplify and automate robot programming for assembly tasks. The basis for this is a purely digital image, i.e. a digital twin, of the production environment. This image, combined with a special programming framework, is used in a physical simulation environment to enable robots to learn skills for flexible assembly. Robots explore their surroundings autonomously in the simulation environment, plan their behavior based on this and optimize it independently or learn continuously.

Artificial intelligence (AI) is used for this, and more precisely machine learning and its sub-area of so-called “reinforcement learning” (RL). This means that an algorithm, similar to humans, learns using the principle of trial and error. He receives a reward signal for a successful action to gradually improve.

The research and development project on AI-based robot calibration (KIRK) aims to use machine learning to develop new software-driven calibration methods for industrial robots in order to increase their accuracy. The initiators of the joint project are the IFF of the University of Stuttgart, the DHBW Karlsruhe and the software manufacturer ArtiMinds Robotics. The Institute for Industrial Manufacturing and Management (IFF) at the University of Stuttgart and the Robot-and-Human-Motion-Lab (RaHM-Lab) at Baden-Wuerttemberg Cooperative State University (DHBW) in Karlsruhe are responsible for the basic research in the project.

Press release by von ArtiMinds Robotics

Press response in the Internet

Article in VDI-Nachrichten

Article in Automationspraxis

Studies

The educational focus ist on teaching AI methods from the areas of machine learning und planning. Students learn, how these methods can be utilized to optimize production processes. Besides theory, practical use cases are considered.

Courses

Student Jobs

If you are looking for a Bachelor-/Master Thesis or a student job in our research area, please contact us.

Marco Huber

Univ. Prof. Dr.-Ing.Deputy Director