Research issues of the department are the biomechanical interrelation of the

direct interaction of humans

- with exoskeletons in the production environment,

- exo and endoskeletal structures in

- preventive ergonomics and

- medical diagnostics and therapy.

For this, we work on the foundations of

- movement, environmental and obstacle detection around the human being,

- intrinsic human motion kinetics and kinetics and

- consequences for the improved and novel mechatronic human-technology interaction.

Projects

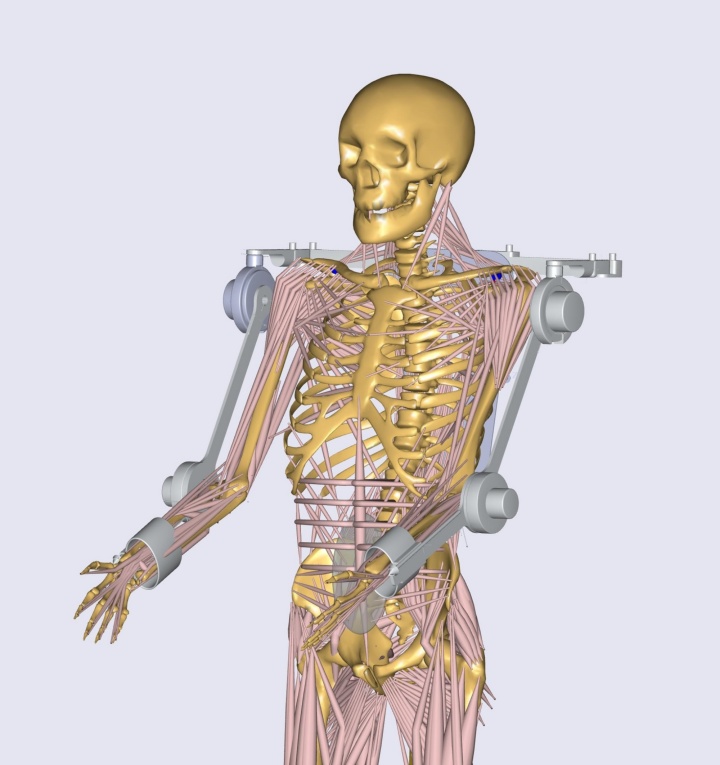

A simulation workflow based on real motion data is built up within the framework of body-worn exoskeleton for partial relief during factory assembly activities. In a musculoskeletal simulation the effects of the exoskeletal solution on the human movement apparatus are examined. This means that validation with regard to kinematics, actuator and control strategy for the exoskeleton can be carried out before the setup and commissioning of the hardware solution.

The scientific work is financed by the Landesgraduiertenkolleg PROMISE 4.0.

The vision of the Cluster of Excellence Integrative Computer Aided Architectural Design (IntCDC) is to harness the full potential of digital technologies to rethink design, manufacturing and construction based on integration and interdisciplinarity, with the goal of building groundbreaking innovations in the construction sector since this is only possible through highly integrative basic research in an interdisciplinary large-scale research enterprise. The aim of the cluster is to provide the methodological basis for a thorough rethinking of the design and construction process and the related building systems by choosing an integrative calculation approach based on interdisciplinary research results in the fields of architecture, structural design, building physics, engineering geodesy, manufacturing and systems engineering as well as computer science and robotics, social sciences and humanities. The Institute for Industrial Production and Factory Operation IFF is involved in this cluster with a sub-project headed by Prof. Thomas Bauernhansl. It will investigate how human-machine interaction can be improved in cyber-physical technologies for design and prefabrication, particularly in exoskeletons in conjunction with Augmented Reality Glasses (AR), and what are the technical and social requirements for the successful implementation of these new technologies , Cyber-physical systems in construction make special demands on the handling of the split control between human, machine and sensor data. Therefore, we will examine the future requirements of these technologies in terms of education, skills and digital literacy. We will explore how to technically optimize human-machine interfaces and how to address and overcome non-technical barriers to innovation, such as lack of relevant skills and qualifications, and resulting attitudes of mistrust, reservations, or rejections along with fears of loss of control. The aim is to increase the acceptance of the technology and thus to promote its acceptance in society and at the level of everyday working life. The aim is to present an exoskeleton / AR (prototype, overhead mounting) application prototype in the demonstrator, the testing of which will allow various levels of human control and concept development of digital competence under conditions of joint control for the future development of cyber-physical construction.

https://www.uni-stuttgart.de/universitaet/aktuelles/schaufenster/intcdc-cluster-film/index

Contact

Dr.-Ing. Nelson Enrique Bances Purizaca

E-Mail:  nelson.enrique.bances.purizaca@ipa-extern.fraunhofer.de

nelson.enrique.bances.purizaca@ipa-extern.fraunhofer.de

Phone: +49 711 970-3711

Cluster Video

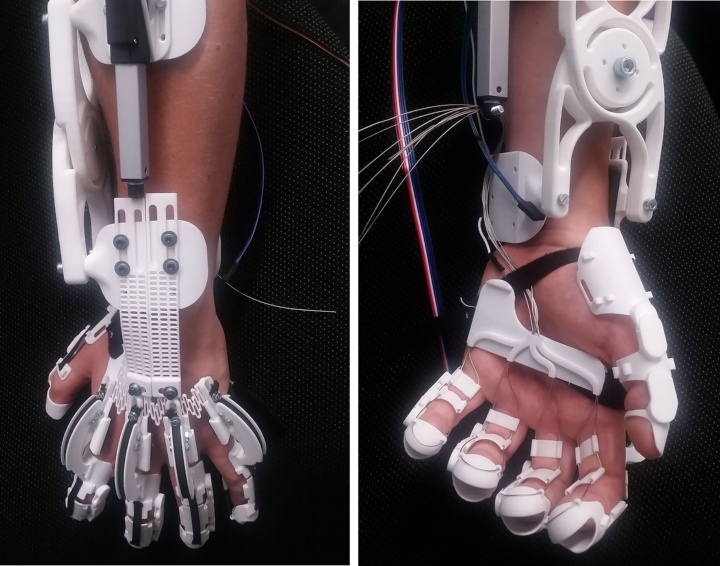

We are developing a non-invasive, neural-controlled hand-exoskeletal system suitable for everyday use that largely compensates for the loss of autonomy and performance due to paralysis of the hand typically occurring after stroke and high cross-sectional injuries. This will be enabled by integrating state-of-the-art EEG-based BMI technology with artificial, context-sensitive, cognitive systems and intelligent bio-robotics.

The project is funded by the Baden-Württemberg-Foundation in the period from 1 March 2017 to 28 February 2020. The project partners are the Eberhard-Karls University of Tübingen, the University of Stuttgart together with Fraunhofer IPA and the Reutlingen University of Applied Sciences.

In Dec 2018 a patent was issued which is being marketed by the Technologie-Lizenz-Büro (TLB) der Baden-Württembergischen Hochschulen. The press release of TLB was met with very good resonance.

Here, the links to some reports and interviews

Focus Gesundheit

Contact

Dr. med, Urs Schneider

Phone: +49 711 970-3630

E-Mail: urs.schneider@ipa.fraunhofer.de

Department Manager

Urs Schneider

Dr. med.Head of Department Human-Machine Interaction